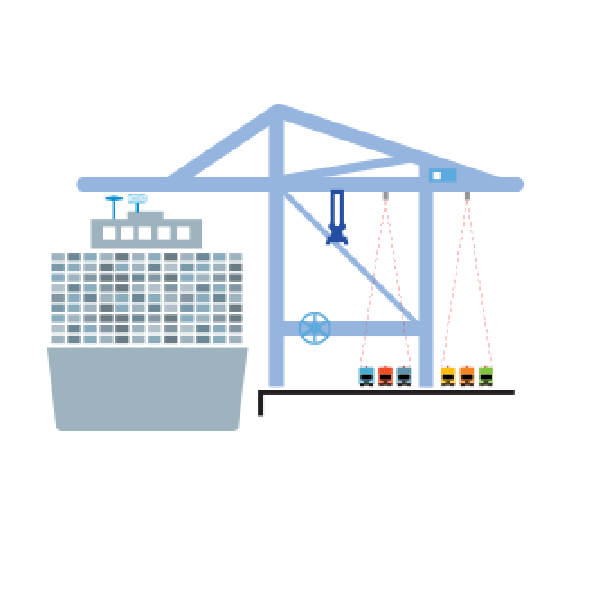

SIRRAH® sensor forms the backbone of our Truck Positioning System.

It is designed to provide better protection for operators and to increase the efficiency of container handling procedures; this device is labour-saving as well as time-saving.

The system can also be used on other types of crane where pre-identified trucks need to be positioned.

Your benefits

Our commitment

Decisive advantages for securing your position vis-à-vis your clients and beyond your competitors

- Productivity: shorter cycle times, faster operations

- Safety: reduced stress and fatigue on the crane operator as well as on hoisting equipment

- Availability and cost-saving: reduced time loss waiting for exact positioning, lower operational costs

- Efficiency and accuracy: efficient positioning and stacking, precise and safe handling

- Reliability and predictability: special design and robustness for severe environments, continuous operation even in harsh ambient conditions

- Sustainability: minimized waiting times thus reducing energy consumption and related CO2 emissions

Accurate and Robust

The sensor technology, its specific design and ruggedness are approved for severe environments; ambient light immunity.

Certified by Arck Sensor

“We are committed to offering robust and accurate products of the highest quality.”

Eric Rumeau, President

Eric Pautal, General Manager